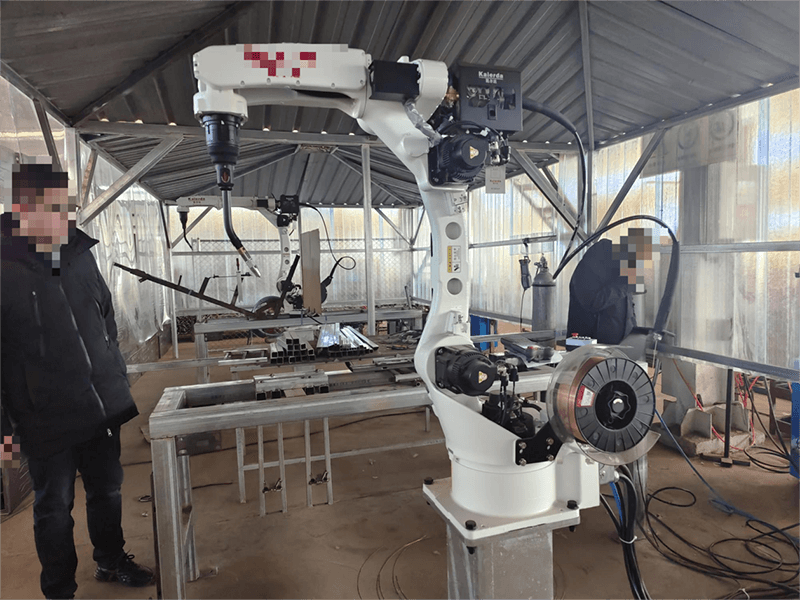

Haufinyane tjena, fektheri ea rona ea tšebelisano-'moho e hlahisitse sehlopha sa liroboto tse bohlale tsa welding, liroboto tse joalo tse bohlale li re thusitse ho etsa lihlahisoa tsa boleng bo holimo le ho ntlafatsa katleho ea tlhahiso le boleng.

Boemo ba boits'oaro le bohlale ba ts'ebetso ea welding bo bonahala haholo maemong a nts'etsopele ea theknoloji ea liroboto tsa welding.Opereishene e tsamaisa motsoako o mong le o mong oa roboto ka har'a tsamaiso ea li-rectangular kapa polar coordinate, e tsamaisa motsotso oa soldering haufi le pina ea welding, e rekota boemo, boikutlo ba nako ea soldering, mekhoa ea ho sisinyeha le mekhoa ea ts'ebetso tseleng ea nako ea soldering, 'me e hlahisa mekhoa e tsoelang pele ea ho ruta lits'ebetso tsohle.

Roboto ea mofuta ona ha e na phoso ea kopano ea workpiece, deformation ea mocheso sebakeng sa phetoho ea ts'ebetso ea welding, hammoho le phetoho ea ntho ea mosebetsi e lokela ho ba le bokhoni, ka hona, ho hlahisa moloko o mocha o na le ts'ebetso e fapaneng ea kutlo, e ka iketsetsa trajectory, tjheseletsa motsotso boikutlo le tjheseletsa parameters ea roboto bohlale e tla ba ka sehloohong ntshetsopele tataiso.

Nts'etsopele ea lisebelisoa tse ncha e tla ntlafatsoa molemong oa ts'ebetso e phahameng, ts'ebetso e phahameng (ho kenyeletsoa ho cheseha hantle) le molemong oa tikoloho.Welding e tla nts'etsapele ts'ebetso e ntle ea welding, e nts'etsapele phepelo ea motlakase e betere le ho nts'etsapele thekenoloji e tsamaellanang ea taolo, ho ntlafatsa tekanyo ea boits'oaro le ho holisa sebaka sa ts'ebeliso ea roboto: fokotsa sekhahla sa sekhechana le sekhahla sa tokiso, fokotsa litšenyehelo tsa ho tjheseletsa, ho ntlafatsa tlhahiso. ho sebetsa hantle (joalo ka: fokotsa, ka mor'a ho futhumatsa pele, mocheso, qoba ho cheselletsa ho chesa, joalo-joalo), felisa khopolo ea "welding ke tšitiso ea mokhoa oa ho etsa tlhahiso".

Nako ea poso: Jun-18-2024